High Quality raw materials are being collected and purchased from different regions and processed as per the Quality standards mentioned in AYUSH DRUG TESTING PROTOCOL for the ultimate quality of final products and to maintain the efficacy of the medicine until its shelf life period.

1) Fresh Herbals:-

Fresh herbals used for the manufacturing are collected around Chennai with the help of well trained and experienced herbal collectors of AROGYA.

2) Dried Herbals and spices:-

High Quality spices and dried herbals are purchased from the traditional supplier who has been in market around 20 years and supplies the original quality raw herbs. Herbs are hygienically packed and transported from various places towards Arogya. Herbs are processed for the cleaning/purification using electrical fitted sand/stone remover sieves.

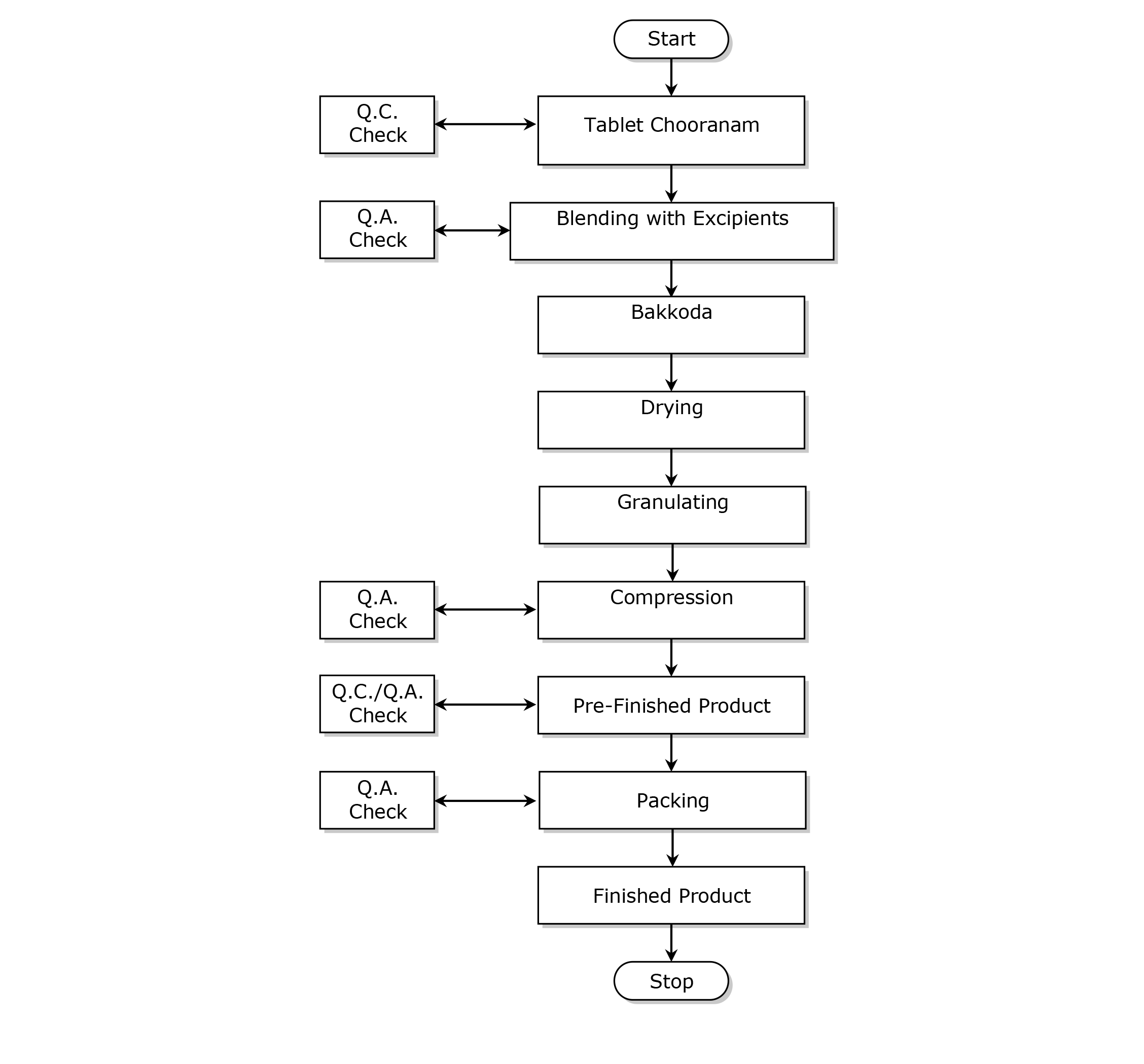

Quality control Check:

Before processing the raw materials, they were subjected to strict procedures of macroscopic and microscopic approval by IN-HOUSE Quality control check, and then checked with standards and reference sample for assuring the Quality and authenticity of raw materials. After QC approval the raw materials are moved for the processing zone.

Juice extracting/Decoction:-

Fresh juice is extracted from the freshly collected herbals using juicer/mixer and juice extractor. Fresh decoction is also prepared using the herbals according with the procedures.

Pulverizing:-

QC passed raw materials are indented according with the original formula of the medicines and underwent for the purification process if needed and get pulverized with the Disintegrator/ Pulverizer for the ultimate fineness in the product.

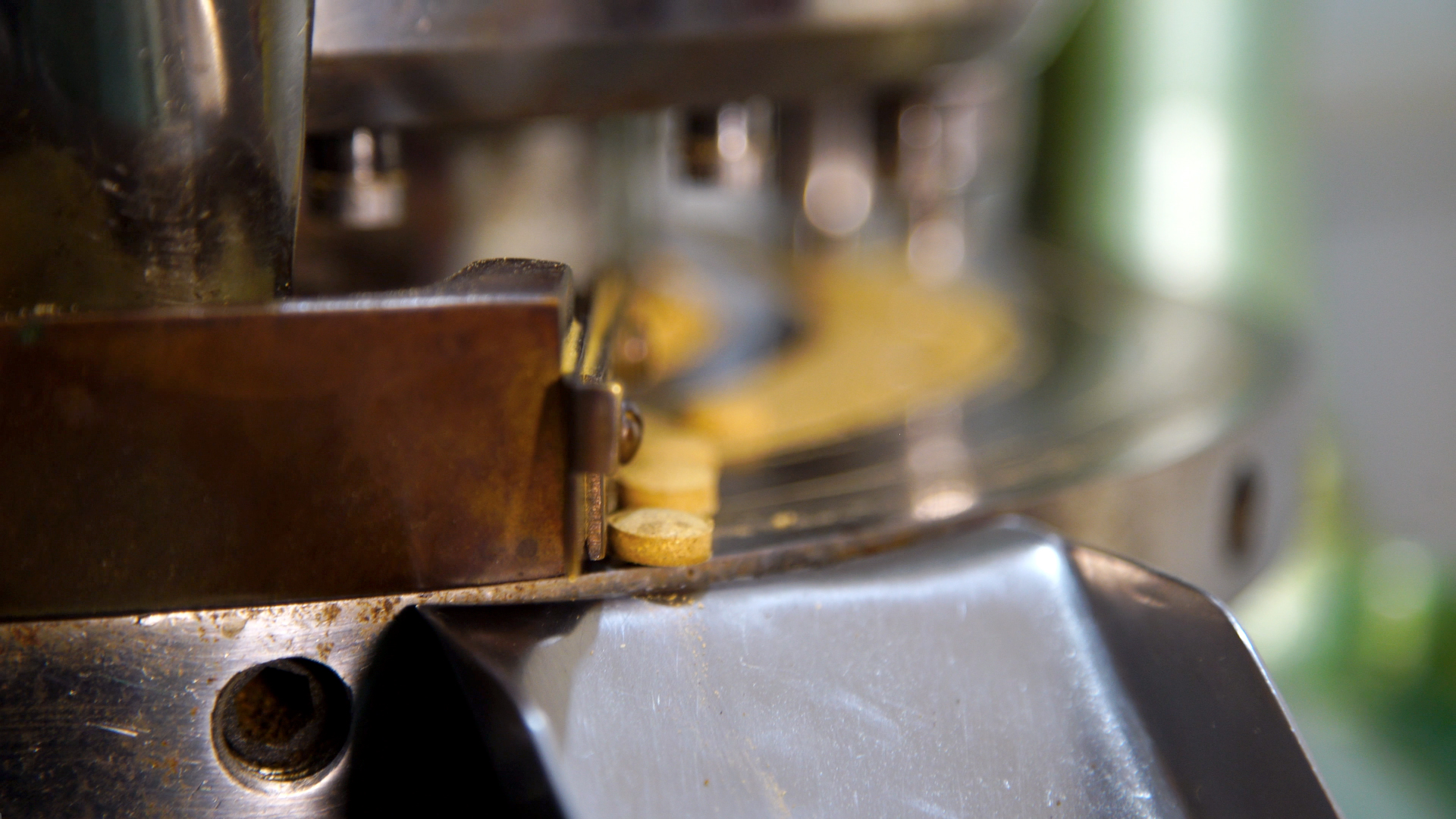

The pulverized herbals are mixed with the herbal juices and dried. The same can be blend with excipients for the tablet preparation using double cone blender and mass mixer. Wet granulation is made and dried. Uniform granules are made with granulator and punched with the 16 station tablet compression machine.

Pre-Finished products are checked with QC for the fineness, product standards, Total ASH, Loss of Drying etc. Several testing are made for maintaining good quality standards of product.

QC approved products are packed according with packing size in hygienic procedures , maintaining the unique batch code for every finished products.

Packed Finished products are subjected for Quality Approval to maintain the Quality standards.